Complete ISO 20345 overview

Certified standards for safety footwear

There are 2 MAIN STANDARDS for safety footwear: ASTM 2413 & EN ISO 20345. Besides these 2 main standards, Safety Jogger pays attention to other safety footwear standards as well (AS/NZS, JIS, LA, SNI, SIRIM, GOST, OHSC) but they are generally based on ASTM & ISO, which are explained below.

ASTM 2413 - 17

The American Society for Testing and Materials (ASTM) is an international standards organization that develops and publishes voluntary consensus technical standards or certifications. ASTM announced in 2005 that their ANSI Standard was withdrawn and replaced by two new ASTM standards, titled F2413 Standard for Performance Requirements and F2412 Standard for Foot Protection Test Methods. These new safety footwear standards provide safety and performance previously put forward by ANSI since 1967.

The biggest difference with ASTM 2413 conforming safety footwear to other standards is that the outsole must be completely insulated for electric shocks. Other requirements for ASTM 2413 conforming safety footwear are impact / compression resistance for the toe area, puncture resistance for safety shoes, and more.

EN ISO 20345 - 11

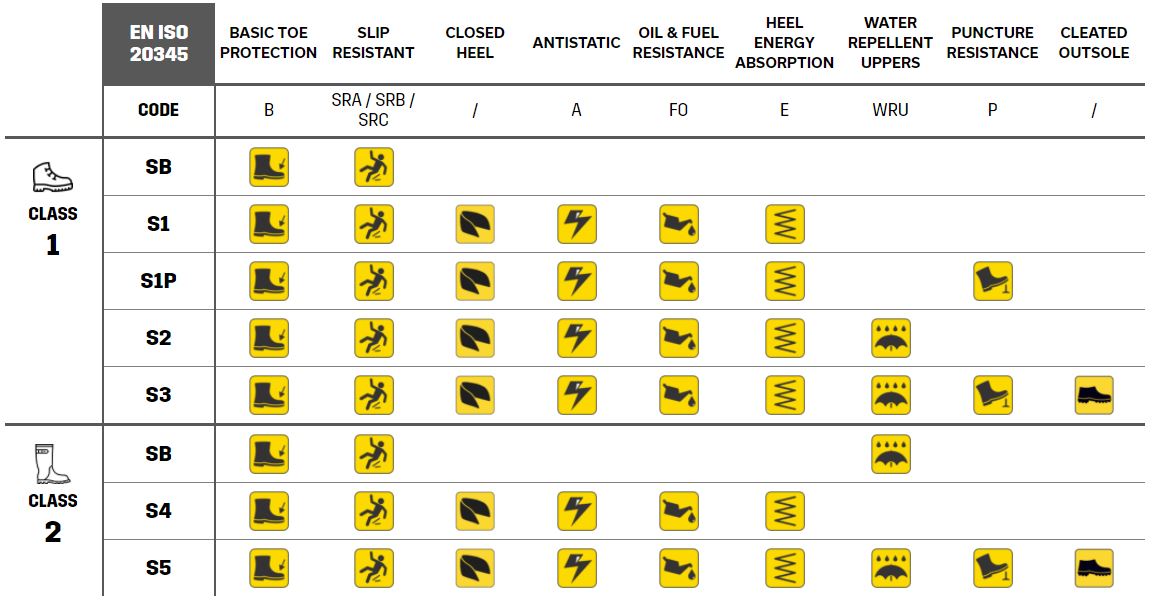

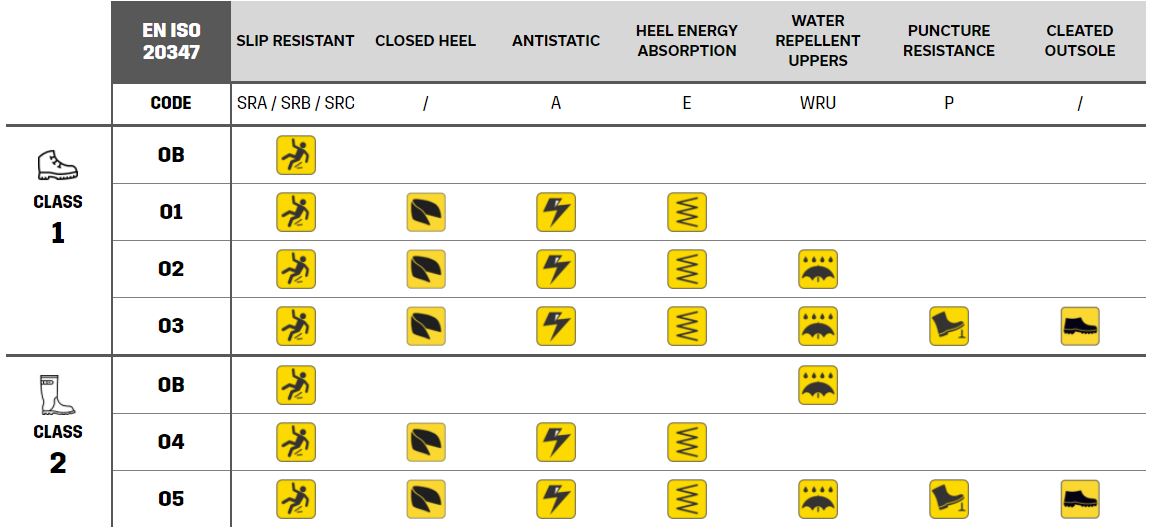

The current safety footwear standard across Europe is updated in 2011 to make it stricter, all products must be manufactured, tested and certified under EN ISO 20345. This safety footwear standard requires all safety shoes to have front foot protection against a 200 joule impact. This is the amount of energy the toe region can absorb before breaking. Under the EN ISO 20345 standard there are different safety classes like S1 or S3 for example. Every safety shoe according to the EN ISO 20345 safety footwear standard will be tested on all possible aspects and will be granted an S-class. Below you can find a complete overview of the minimum requirements for each safety class within the EN ISO 20345 safety footwear standard.

Safety footwear ISO standard EN ISO 20345

Safety footwear that requires a safety toecap

Occupational footwear ISO standard EN ISO 20347

Safety footwear that does not require a safety toecap

Do you need any advice or do you still have some questions left about safety footwear standards and certifications? Don’t hesitate to contact us right away, We're social!

You might also like to read

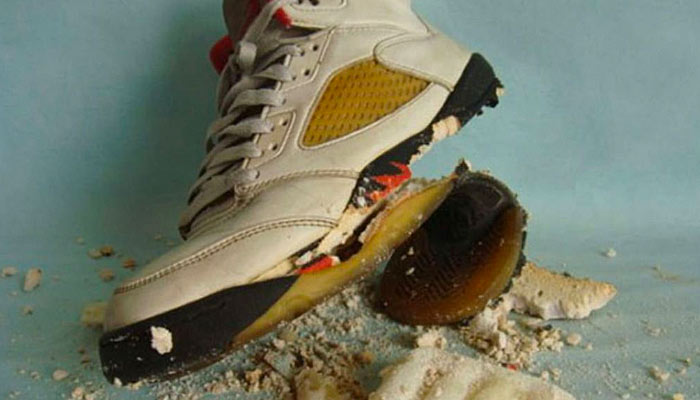

Hydrolysis, the crumbling of shoe soles explained

Why does my shoe fall apart? This is How We Prevent Hydrolysis in Our Safety Shoes. One of the main technical challenges with polyurethane shoe soles is overcoming an ageing deterioration known as ‘hydrolysis' ...

Hydrolysis

Breathable leather work boots

Leather work boots mean you are wearing pure quality: resistance to tear / breathability / flexibility / high resistance to puncture & much more ...

Leather bootsGROW YOUR BUSINESS & BECOME A DEALER

Safety Jogger is worldwide and always looking for people who trust our brand as much as we do! We have a team of expert's ready for you to help with questions about our brand, technologies or reselling our products. So, don’t hesitate to fill in this form, we usually get back to you within a day!

Further information?

Fill in the form and we’ll get in touch!