Our sustainability strategy

Our performance was evaluated across four key areas, each reflecting our commitment to sustainability. Here’s how they shape our daily work:

We operate on 100% renewable electricity and are committed to achieving net-zero emissions for Scope 1 and 2 by 2030. We also aim to reduce the carbon footprint of our product designs (our key scope 3 emission) by 30% by 2035.

All our factories are BSCI-approved, ensuring fair labour practices, ethical working conditions, and respect for human rights across our supply chain.

We aspire to ensure a responsible supply chain with respect for social rights and the environment and want all our Tiers 1 suppliers and our nominated Tier 2 suppliers to be third-party audited by 2030.

We lower our impact through sustainable materials and ecodesign. Using life cycle analysis and PEF scoring, we guide material choices to create high-quality products with reduced environmental impact.

Since day one, our 4C-strategy has guided every decision we make.

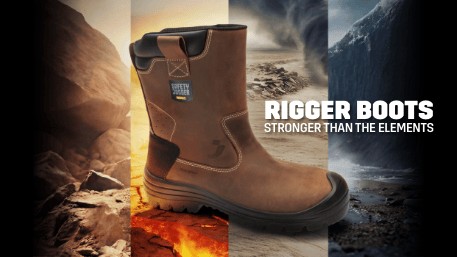

“At Safety Jogger, the safety of the wearer always comes first. Every product we create must meet the highest ISO standards to guarantee reliable protection. Within these standards, we challenge ourselves to innovate and explore more sustainable materials. Our goal is to combine safety and sustainability without compromise. That commitment defines who we are and how we move forward.”

- Tom Gybels, General Director Safety Jogger Works

To further strengthen this approach, we selected the Great Place To Work Trust Model as our framework and in 2025, we will initiate the process to achieve the Great Place To Work certificate.

To further strengthen this approach, we selected the Great Place To Work Trust Model as our framework and in 2025, we will initiate the process to achieve the Great Place To Work certificate. In addition to our internal focus, we are dedicated to supporting those in need within our communities. We concentrate our efforts on three key areas: mental well-being, poverty alleviation, and quality education. We support charity organizations working in these areas through financial aid and product donations.

In addition to our internal focus, we are dedicated to supporting those in need within our communities. We concentrate our efforts on three key areas: mental well-being, poverty alleviation, and quality education. We support charity organizations working in these areas through financial aid and product donations.

We already calculated our scope 1 and 2 emissions, as well as parts of our scope 3 emissions. We aim to have a full, GHG-protocol-based carbon footprint calculation by 2025.

To improve our carbon footprint, we already switch to 100% renewable electricity (scope 2) and aim to achieve also net-zero for scope 1 by 2030.

However, most of our carbon footprint arises from scope 3 emissions, which are predominantly associated with the materials we use in our products.

To address this, we integrated the carbon footprint of our materials in our automated scoring tool as well (see eCodesign). This will allow us to also focus specifically on minimizing the carbon footprint of our designs, with a 30% reduction target by 2035.

Download our 4 C sustainability strategy