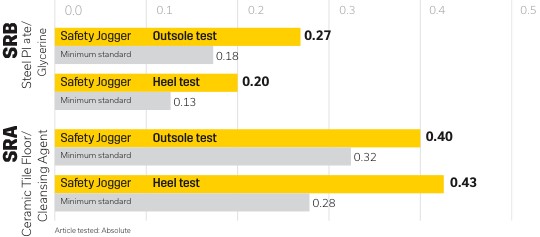

Slip resistance: what is the difference between SRA, SRB and SRC?

Did you know that slipping, tripping and falling are the main causes of accidents on the work floor? That is why Safety Jogger offers a wide selection of shoes with an outsole that exceeds the general European slip resistance standards by far.

However, it’s important to know that some shoes on the market claim to be ‘slip resistant’ without them being formally tested in a laboratory. You can only be 100% sure your safety footwear is slip resistant when your shoes have a slip-resistant rating like SRA, SRB or SRC. But what is the difference between these three ratings? Watch the explanation in the video below:

In summary:

Safety Jogger SRC slip-resistant soles pass both the SRA and the SRB test with glance. They not only fulfill the minimum standards but exceed them remarkably! You will notice that almost every Safety Jogger shoe is provided with an SRC-certified slip-resistant sole.

You might also like to read

Lightweight work boots for sensitive feet

What makes a lightweight work boot? Every vital element, the protective toe, outsole, upper material, lacing hardware, linings, insoles, .. contributes to the final weight of a lightweight work boot.

Lightweight boots

Which toe cap material is the best choice for you?

A protective toecap made according to European or ASTM standards will protect your toes from basically every injury, regardless of the material. But what materials are there and what is the difference?

Steel or composite toe

Waterproof work boots & shoes

More than likely you’re going to get caught up in the rain at some point on a regular workday. When you do get caught in a downpour, generally you’ll come home taking of those wet socks to spot a pair of wrinkled feet.

WaterproofGROW YOUR BUSINESS & BECOME A DEALER

Safety Jogger is worldwide and always looking for people who trust our brand as much as we do! We have a team of expert's ready for you to help with questions about our brand, technologies or reselling our products. So, don’t hesitate to fill in this form, we usually get back to you within a day!

Further information?

Fill in the form and we’ll get in touch!